Top Most Industrial Conveyor Belts Manufacturers, Suppliers & Exporters in India

Material handling in manufacturing, mining, logistics, packaging, food processing, and many other industries depends on industrial conveyor belts. Conveyor belts are designed to move materials efficiently, and this will save companies money on labor, enhance their productivity, ensure continuous operations, and keep the workplace safe. The need to have durable and high-performance conveyor belts is on the rise as industries continue using automation. It is here that the place of a reputable Conveyor Belt Manufacturer, Supplier is needed.

Key Features

1. Superior Material Strength

High-grade materials like rubber, PVC, PU, nylon, and steel reinforcement are used in the design of high-grade conveyor belts. The materials improve belt strength, and it can bear heavy loads, sharp objects, and operate continuously.

2. Heat, Chemical, and Abrasion Resistance

Harsh conditions are common in industrial environments. A quality conveyor belt should be able to withstand heat, oils, chemicals, and abrasive substances so that it can give long life without instances of replacement.

3. High Load-Carrying Capacity

Conveyor belts are used to transport coal, cement, grains, packaged goods, and so on; therefore, they have to remain stable at high pressure. Belts produced by the major brands are characterized by great load-carrying capacity and flexibility.

4. Easy and Fast Material Transport

The conveyor belts of today are designed to have steady motion with minimal vibrations, noise, and energy usage. This is a smooth running resulting in advanced throughput and operational efficiency.

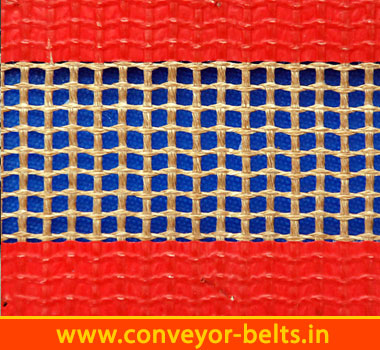

5. Customizable Design

The requirements of every industry vary. Selectable conveyor belts from reliable manufacturers include the width, thickness, material, pattern, and tensile strength of conveyor belts to suit an industrial activity.

Conveyor Belt Types in Industries

Uses of Industrial Conveyor Belts

- Mining & Quarrying

- Cement & Concrete Plants

- Steel & Metal Processing

- Food & Beverage Industries

- Pharmaceuticals

- FMCG & Packaging Units

- Warehousing Distribution Centers.

- Chemical Industries

- Airport Baggage Handling Systems.

- Recycling Plants

- Plants, Agriculture, and Fertilizers.

All these various applications indicate the necessity of selecting the appropriate Conveyor Belt Supplier with knowledge of industry needs.

Role of a Conveyor Belt Manufacturer

A reliable Conveyor Belt Manufacturer is a major player in providing good and efficient conveyor solutions. They are expected to work on:

Role of a Conveyor Belt Supplier

The best Conveyor Belt Supplier is an intermediary between the industry and industry purchasers. Their role includes:

Role of a Conveyor Belt Exporer

Why Choosing the Right Manufacturer, Supplier & Exporter Matters

- Assures cost savings in the long term.

- Reduces downtime and maintenance.

- Offers quality belts specific to your industry.

- Ensure material handling is safe and efficient.

- Facilitates easy industry functions.

- Delivers international-quality performance and stability.

Be it a Conveyor Belt Supplier, selecting the right partner guarantees you the best possible payoff.

Conveyor belts used in the manufacturing and material-handling systems of modern industry are necessary elements. Their work has a direct influence on the productivity, efficiency, and safety of industries on a global level. The collaboration with the appropriate Conveyor Belt Exporter, Manufacturer provides access to high-quality, durable, and industry-specific conveyor solutions. The importance of the trusted conveyor belt expert is bigger than ever since industries keep adopting automation and sophisticated material handling systems.