Industrial Conveyor Belt Manufacturers, Suppliers & Exporters in India

Welcome to Shetty Enterprises, a premier name among conveyor belt manufacturer & supplier since 1999. With over 25 years of experience, we offer rubber, PVC, PU, and specialized belts meeting FDA and ISO standards. Every product is designed with high-quality raw materials and precision engineering technology to endure heavy loads, abrasion, moisture, heat, and chemical exposure, as it is usually applied in Indian industries. As conveyor Belt Manufacturers, we deliver reliable performance, smooth operation, and long service life across demanding industrial environments.

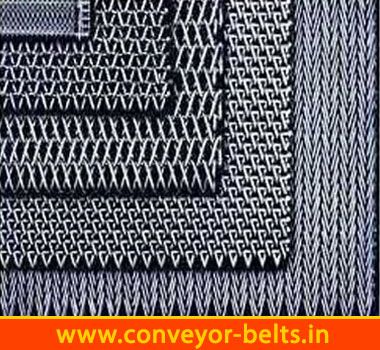

We have developed almost all types of special conveyor belt suppliers to suit the needs of practically all types of Industries. We are a Leading Supplier of Rubber Conveyor belts in various grades like N-17, M-24 Grade, SAR Grade, HR Grade, SHR Grade, UHR Grade, CMR Grade, OR Grade, Food Grade, FR Grade, And Chevron Conveyor Belts.

What are Conveyor Belts?

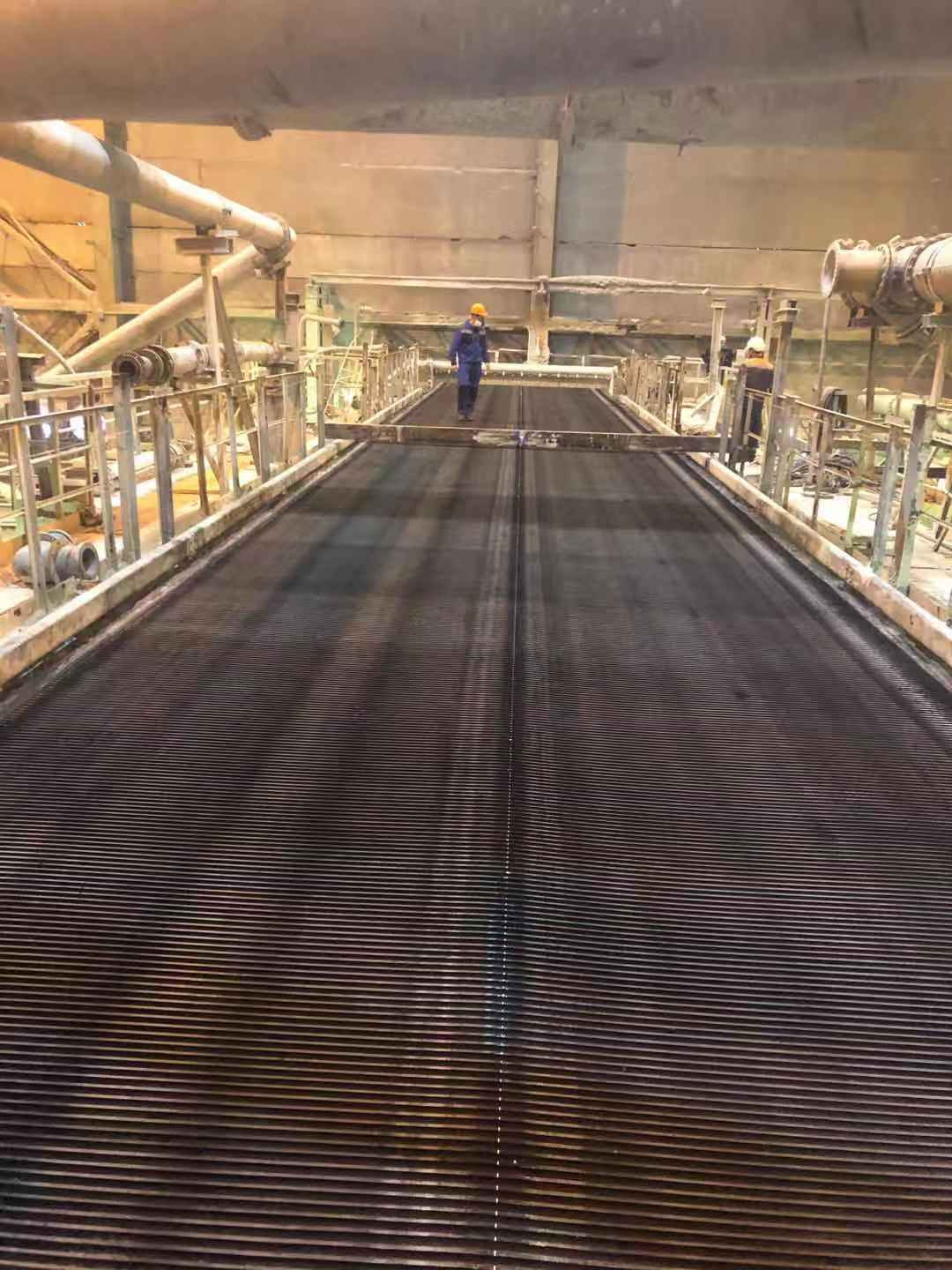

A conveyor belts is a moving, continuous belt that is used to carry goods or products within a material handling system, typically moving along a fixed route within a factory, warehouse, airport, or mine. Fabric, PVC, PU, or rubber constructed with various load caps, speeds, and work conditions.

How does a conveyor belt work?

- Power Source: Electric motors turn pulleys.

- Drive Pulley: Transfers the belt and materials to drive them.

- Tail Pulley & Rollers: Serves as a support and guidance for belt movement.

- Conveyor Belt Material: Conveys objects along specified routes.

- Tension System: Maintains the correct, tight, and centered belt alignment

The Main Components of the Conveyor Belt System

Benefits Of Conveyor Belts

- No transfer points

- No spillage with steep angle conveying

- Maximum utilization of space

- Minimum maintenance long belt life

- A wide range of materials can be handled

- Low Power requirement, quite a smooth running

- Ability to carry almost any bulk material

- High reliability of operation

- Can transport material in any direction

our product quality

- Versatile

- Cost effective

- Greater longevity

- High reliability

- Impeccable

Technical Specification

| Feature | Detail |

| Material Base | PU, PVC, Nitrile, Silicon, Rubber |

| Belt Thickness | 1mm to 10mm (Customizable) |

| Temperature | -20°C to +120°C |

| Tensile Strength | High-strength polyester fabric carcass |

| Compliant | FDA, EU Food Grade, ISO 9001:2015 |

Industrial Conveyor Belts Manufacturer – Shetty Enterprise

Shetty Enterprise top-notch industrial conveyor belts manufacturer and supplier throughout India. We offer a wide selection of M24 Conveyor Belts, Heat Resistant Conveyor Belts, Chevron Conveyor Belts, Modular Belts, PVC Belts, and Rubber Conveyor Belts. Our products last long, work well and give good value for money in many industries. The high-quality solutions we provide meet industry standards and perform to handle all your conveying tasks.

Why Choose Shetty Enterprises?

Custom Engineering: We don’t just sell belts; we design solutions. From saw-tooth profiles to ultrasonically welded cleats, we customize every belt to your machinery.

Global Export Footprint: We are recognized conveyor belt exporters, serving clients in the USA, Germany, South Africa, Saudi Arabia, and beyond.

Certified Quality: Our ISO 9001:2015 certification ensures that every meter of belting undergoes rigorous stress and friction testing before dispatch.

FAQs

The conveyor belts move material and transport items. The conveyor belts are used to carry material and transport items. I have observed the conveyor belts, food processing, Asian model packaging, logistics, textile, mining and manufacturing.

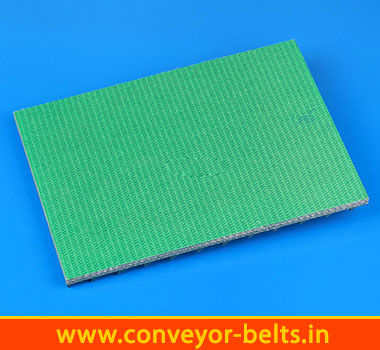

The PU conveyor belts, the food conveyor belts and the rubber conveyor belt. The other similar ones include the cleated conveyor belts, the sidewall conveyor belts, the cooling tunnel conveyor belts and the textile conveyor belts.

I chose the conveyor belt by looking at the material type. The right conveyor belt also depends on the load capacity, the operating environment, the temperature conditions, and the conveyor system design requirements.

I can confirm that food conveyor belts are made with food‑grade materials. Food conveyor belts meet the hygiene and safety standards required for food processing and packaging applications.

The industrial conveyor belts move items in food processing, packaging, pharmaceuticals, agriculture, recycling, logistics, textile and manufacturing.

Yes, the conveyor belts can be made in widths, thicknesses, many material types, many cleat designs and many surface finishes.

The Rubber conveyor belts cost between ₹200 and ₹800 per meter. The PU conveyor belts cost between ₹500 and ₹1500 per meter, depending on the grade and the details.

From my experience, PU conveyor belts are best for the food and hygiene-sensitive industries. PU conveyor belts keep the product safe. Rubber conveyor belts are the choice for the duty industrial material handling jobs. Rubber conveyor belts can move the loads.

Shetty Enterprise offers durable, high-performance conveyor belts designed for multiple industries with customization options and reliable manufacturing expertise.