Dairy Conveyor Belts

India's Best Conveyor Belts Manufacturer, Supplier & Exporter

PVC Conveyor Belts

India's Best Conveyor Belts Manufacturer, Supplier & Exporter

Food Conveyor Belts

India's Best Conveyor Belts Manufacturer, Supplier & Exporter

India's No.1 Branded Conveyor Belt Manufacturer, Supplier & Exporter

We, Shetty Enterprise, are a conveyor belt manufacturer widely worn in high-quality industrial conveyor belt solutions for various industries such as food processing, heat treatment, forging, foundry, glass, ceramics, automotive, furnace, etc.

for transporting assorted goods from one place to another. We as a conveyor belt Manufacturer that is convenient for any application, along with closed wire mesh belts for flexibility and conveying small parts. As a leading conveyor system manufacturer, we offer PVC conveyor belts, PU conveyor belts, metal detector conveyor belts, saw tooth collar fusion conveyor belts, Ultrasonic welded side wall conveyor belts, cut to length sheets conveyor belts, treadmill belts and more.

Why Choose Us?

We maintain our Addment to offering the most suitable rubber products to our Customers and we believe in Constructing a durable relationship with them. the quality-ensured bad is procured from our worthy vendors and the factory-made products get different character checks to check amp defect-free variety for our Customers. Further, for the well-being of the clients, we obtain diverse payment modes. Moreover, by following a customer-centric approach, we have been able to cater to a huge clientele. Due to our ethical business policy, we are well-appreciated by our enormous clientele.

Premier Manufacturer of PVC Conveyor Belt in Ahmedabad

It is the quality of our PVC/PU based customized conveyor belts that ensure safety along with efficacy.

Conveyor belts, which include large openings for easy flow of water or air and for cleaning your products, and smooth surface belts for easy and careful transfer.We are thoroughly dedicated to producing the best quality of Conveyor Belts.

We are a highly prominent organisation engrossed as a foremost manufacturer, supplier, and exporter of brand-named conveyor belts that are manufactured with specially engineered food-grade polymer to manufacture these belts, which are extensively established for their admirable quality and high achievement in conveying, washing, cooling, and drying applications. We have designed our conveyor belt according to the food processing, FMCG, and heavy-duty assembly lines, these belt aspects guarantee food safety and persistence. We have developed the conveyor belts by utilizing superior-grade raw materials under the scrupulous quality supervision of these manufacturing processes, which can be arranged in smooth and spiral designs at the most competitive price.

wE SERVE INDUSTRY FOR CONVEYOR BELTS

We consider arranging the right and suitable cleated conveyor belts, as it helps them use them in an effective way. Our offered cleated conveyor belts are produced based on the requirement, which helps people use them for longer. We are adept at producing a huge assortment of cleated belts, which can be utilized in diverse places. Cleated conveyor belts are uniquely utilized for the movement of materials in the packaging industry, and our products are acknowledged for their modular design. We manufacture the cleated conveyor belt using premium-quality materials and are acknowledged for its durability and lightweight. Moreover, the conveyor belts provided are relevant for work support in transferring goods in areas like ports, mines, foundries, food supplies, fertilizer, and others.

We are among the esteemed names in the industry for manufacturing and exporting premium-quality food conveyor belts. Our manufactured Food Conveyor Belts are widely utilized in the food processing industry for washing, baking, blanching, dewatering, cooling, freezing, and pasteurising. These food conveyor belts are resistant to corrosion, rusting, oxidation, and wear and tear. They are non-reactants to acids and alkalis, owing to their inert nature and the use of high-quality material for making them. Our offered belts are FDA/USDA-approved for use in food applications, with cleats and top covers moulded in an analogous process to provide a smooth, seamless top surface for easy cleaning in demanding hygienic conditions. The committed cavity establishes that the belts contain a high-quality, clean, and sanitary surface.

Shetty Enterprise is placed among the notorious manufacturers, suppliers, and exporters of an exhaustive assortment of PVC Conveyor Belt. We are manufacturing these PVC Conveyor Belts under the set international standards, utilizing high quality raw materials. Our clients can avail the conveyor belts in diverse specifications and can be modified as per their specific requirements. Besides, this belt is also known for its unique attributes like flexibility, fine finish, durable finish standards, and robustness. Our manufactured conveyor belts with PVC surfaces of various types such as plain, smooth, rough top, high super grip, diamond, etc., are extensively utilized in a variety of industries, such as textile, pharmaceuticals, food, packaging, etc. for any conveyor purposes.

Shetty Enterprise is a well-known brand in the industry as a foremost organization known as a manufacturer, supplier, and exporter of Textile Conveyor Belt that carry out an ample assortment of conveyor tasks in all the flourished industries. Depending on the application, textile conveyor belts feature diverse cover stock properties and a single – or multi-ply textile tensile member. Further to a range for regular bulk goods, various special types are accessible for conveying hot goods, for the transport of goods containing oil and grease, for steep-incline conveying and with special reinforcing materials for particular applications.

We are a leading manufacturer of Vegetables Conveyor belts which are utilized in the food processing industry and require strong and wear-resistant belts. With the support of the Vegetable conveyor belts, the vegetables need to be handled or processed quickly while they are fresh. Moreover, for our manufactured conveyor belts, we provide highly durable, abrasion-resistant, easy-to-clean modular belting products, stocked and built on-site, with 24-hour field service and installation of modular, fabric, and non-fabric belts. This assurance of superiority has helped us build a reputation for rock-solid consistency and an ultra-low cost of ownership.

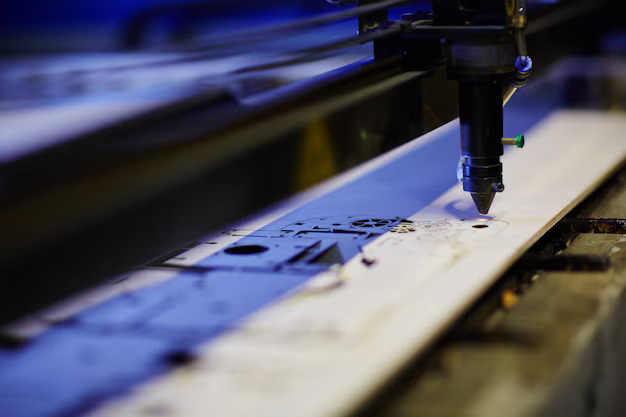

We are determined in this domain to be one of the most dependable manufacturers, exporters, and suppliers of Cutting Machine Conveyor Belt. Our active professionals utilize flawless quality components and ultra-modern techniques to manufacture this machine as per the set universal standards. Our manufactured conveyor belt is generally demanded to cut various kinds of fabrics and belts to desired lengths. We satisfy our customers that this machine is closely examined for set quality parameters before dispatching at our client’s end. Besides, these conveyor belts can be availed of by our esteemed clients in different technical specifications at economical prices.

We have been considered the leading metal conveyor belt manufacturer for over a century. Our metal conveyor belts and chain-driven conveyor belts are utilized globally in industries such as heat treating, forging, foundry, food processing, snack food, baking, ceramics, glass, automotive, and many more. We are manufacturing these conveyor belts with the support of a skilled team of professionals employing advanced machines and tools. Our metal conveyor belts offered include a left-hand and right-hand spiral, connected with a striped cross rod. In our offered conveyor belts, the stress of these spirals on both sides is properly balanced, resulting in a smooth, straight belt with minimum expansion along the length or width.

We are an outstanding manufacturer and also understand uptime and conveyor belt requirements. For the same, we are offering a complete range of quality control in our manufactured Packaging Conveyor Belt that is designed for fabrication, research, and development, as well as prototyping and installation. Our manufactured packaging conveyor belts have stainless steel table tops with an endless sandwich belt in the centre of the table. These packaging conveyor belts are mainly utilized to move the object for filling, threading, sealing, capping, etc. Further, this helps in visual inspection for primary packing, secondary packing, picking, and placing at the proper place.

We are Leading World Wide Conveyor Belt Exporter

Key Tags